Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Ingredient Name

- Raw Material Origin

- Base Chemicals Functions

- Food Ingredients Functions

- Industrial Additives Functions

- Molecular formula

- C₆H₁₀O₆

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Food Ingredients Features

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

Properties

- Physical Form

- Soluble In

- Odor

- Nearly Odorless

- Soluble in

- Water

- Sparingly soluble in

- Ethanol

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (at 20°C) 1,720 g/cm³ - Boiling Point 153 - 155 °C - Melting Point 153 - 155 °C - Molecular Weight 178.15 g/mol - Bulk Density 600 - 1,000 kg/m³ - Molecular formula C₆H₁₀O₆ - - pH (at 1% Concentration, 2h in aqueous solution) approx. 2.6 - - Solubility in Water (at 20°C) approx. 587 g/L - Appearance Crystalline powder - - Vapor Pressure (at 25°C) max. 0.00001 hPa - Decomposition Temperature min. 150 °C - Flammability Not auto-flammable - - Odor Slight, none - - Dust Explosion Class St1 - - Color White - - - Characteristics

Value Units Test Method / Conditions Melting Point 150 - 154 °C - - Specifications

Value Units Test Method / Conditions Reducing Substances max. 0.5 % - Assay 99 - 100.5 % - Water Content max. 0.15 % - Chloride Content max. 50 mg/kg - Sodium Content max. 30 mg/kg - Sulfated Ash Content max. 0.1 % - Granulation (at > 0.25 mm) max. 5 % - Granulation (at < 0.075 mm) max. 5 % - - Heavy Metals

Value Units Test Method / Conditions Lead Content max. 1 mg/kg -

Regulatory & Compliance

Technical Details & Test Data

- Technical and Test Details

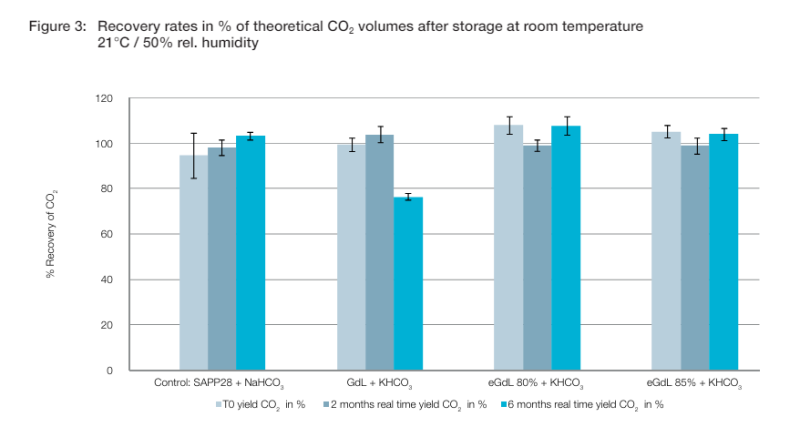

With storage at room temperature (figure 3) the recovery rates after six months showed the stability of the combinations of encapsulated GdL with KHCO3 to be excellent. Only the combination of the non-coated GdL/KHCO3 showed a significant decrease of CO2 recovery to less than 80%.

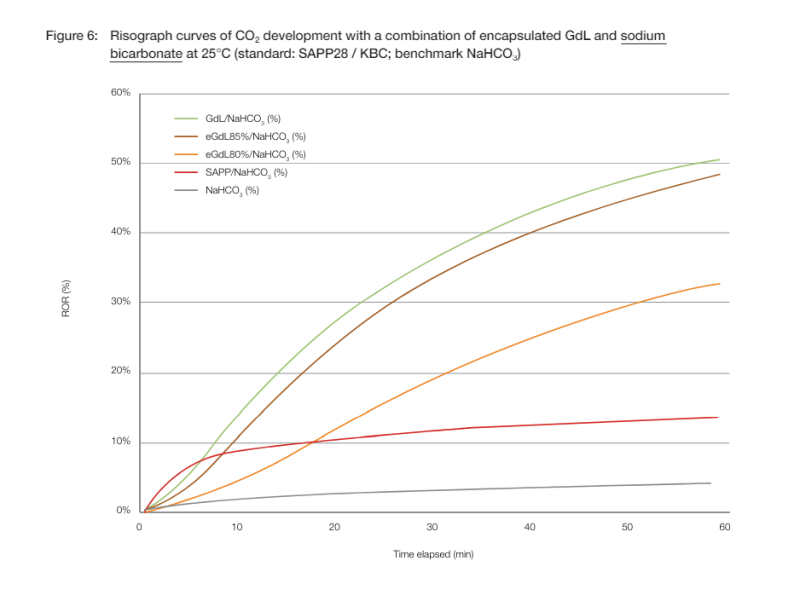

The curves in figure 6 detail the cumulated CO2 development over time of the baking powder combinations with sodium bicarbonate at 25°C. The benchmark combination SAPP28/NaHCO3 reached a total CO2 development of 15% after 60 min. The non-encapsulated GdL in combination with NaHCO3 reached a total CO2 development of 50% in the first 60 min. For the combination eGdL80%/NaHCO3, the CO2 development remained below the benchmark for the first 17 min and rose to 30% at 60 min. The combination eGdL85%/NaHCO3 showed behaviour more similar to the non-encapsulated GdL and reached a total CO2 development of 47% after 60 min.

Achieving the best texture and stability of silken tofu with Glucono-delta-Lactone

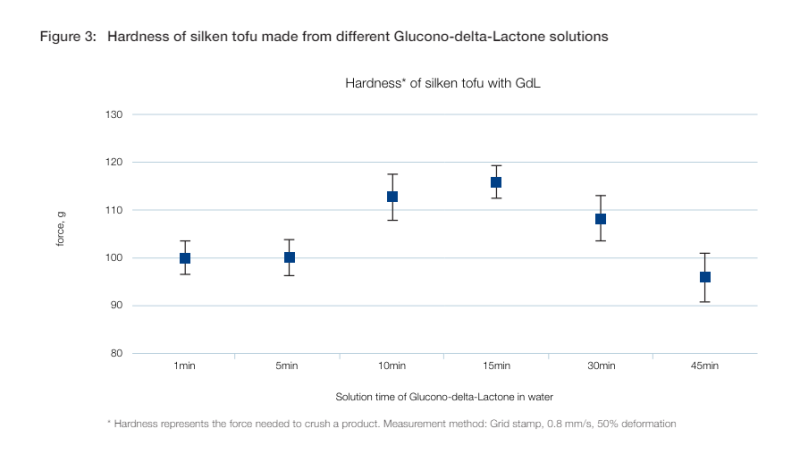

Silken tofu was prepared from GdL solutions that were stirred for 1 - 45 minutes. Five batches of silken tofu were produced from every solution and measured for their hardness using a texture analyser. Figure 3 shows the firmest silken tofus were obtained when the GdL solution was stirred for 10 - 30 minutes, whereas shorter or longer times resulted in softer tofu. A similar trend was observed when analysing the breaking strength of these same samples (data available on request).

How does Glucono-delta-Lactone perform in comparison to other coagulants?

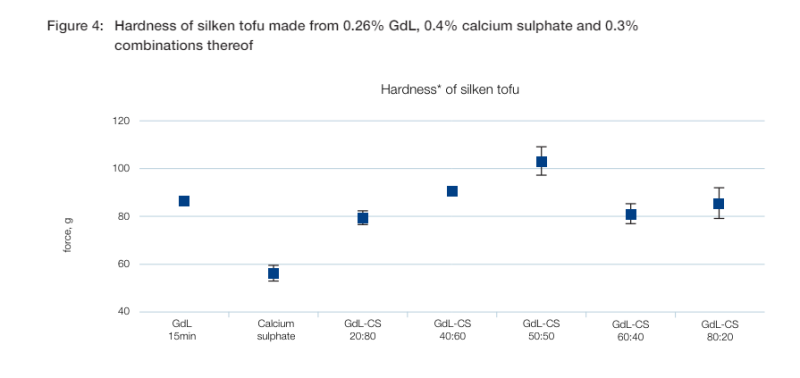

Calcium sulphate is another well-established coagulant and widely used. Silken tofu was prepared with 0.26% GdL, with 0.4% calcium sulphate or with combinations of both in varying ratios (total coagulant concentration 0.3%). The hardness of the tofu obtained using the single coagulants or the mixtures was analysed (figure 4). GdL produced firmer tofu than calcium sulphate when using soymilk taken from the same batch. This confirms reports by Cheng et al. (2005). A combination of the two coagulants at a ratio of 50:50 led to increased firmness. This finding suggests that the hardness of silken tofu produced traditionally with calcium sulphate can be enhanced by a partial replacement with GdL.

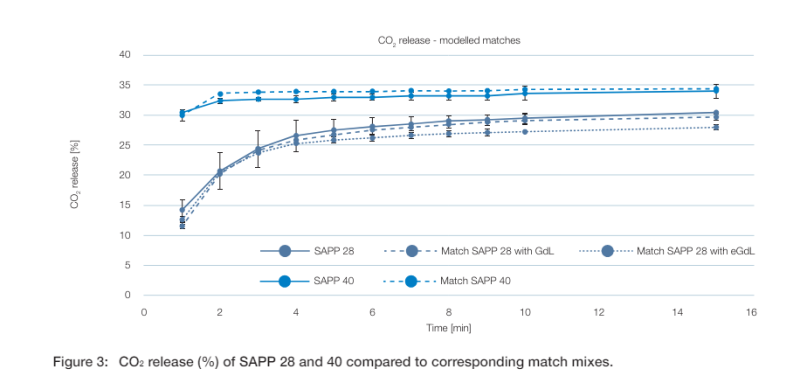

The SAPP types were reproduced by calculating the CO2 release rate of SAPP and the equivalent amount of Jungbunzlauer acids applied. Blends of the Jungbunzlauer acids were produced to achieve CO2 release kinetics matching those of the four types of SAPP (“SAPP match mixes”).

As shown in figure 3, the kinetics of SAPP 28 and 40 were modelled successfully. Two different match mixes were developed for SAPP 28. The match mix with GdL would be the perfect choice in terms of kinetics but is less stable over storage time, whilst a second version with eGdL (S290 T) has minor deviations in kinetics but better storage stability.

Packaging & Availability

- Packaging Type

- Supplied by

- Packaging Information

- Jungbunzlauer glucono-delta-lactone is available in 25 kg net polyethylene (LDPE) bags or in 1000 kg net polypropylene big bags.

Storage & Handling

- Storage Conditions

- Fine, White, Nearly Odourless, Crystalline Powder"