Enhanced TDS

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Product Highlights

- Degreasing, mineral oil vegetable fat and charred fat: In industrial cleaning, dirt usually contains mineral oil/grease and particles. To emulsify mineral oil the pH is not important, but to have good dispersing of the particles the pH should be ~11. When the oil/grease is charred and difficult to emulsify a high amount of caustic is necessary to boost performance. Berol LFG 61 work well in this situation.

- Pigment removal and dispersing: To remove particles and to keep them dispersed in the solution so they do not re-deposit onto the surface is important in all cleaning applications. For example in vehicle cleaning dirt contains a lot of particles, not only from the road but also from pollution from the air. These particles, “traffic film”, are extremely small and very difficult to remove in touchless/brushless machines, which have become more and more common today. Using highly alkaline cleaning formulations, enabled by using Berol LFG 61, helps lift such soils from vehicle surfaces, keeps them dispersed and enhances vehicle cleanliness.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

Properties

- Physical Form

- Dispersible in

- Octanol, propylene glycol, water (max. 5%)

- Soluble in

- High electrolytes, weak and strong acids

- Characteristics

Value Units Test Method / Conditions Active Content 95.0 % - Clear Point -15.0 °C - Cloud Point (at 5% in Water) 33 °C - Flash Point min. 100 °C PMCC Pour Point 0.0 °C - Specific Gravity 1.1 - - Surface Tension (at 0.1% Solution) 31 dynes/cm - Viscosity 1800 cPs - Wetting Power (at 25°C, 0.1% Solution) min. 600 seconds Draves Wetting Test - Specifications

Value Units Test Method / Conditions Color 0 - 10 - Gardner pH 7.0 - 9.5 - - Water Content 4 - 6 % -

Regulatory & Compliance

Technical Details & Test Data

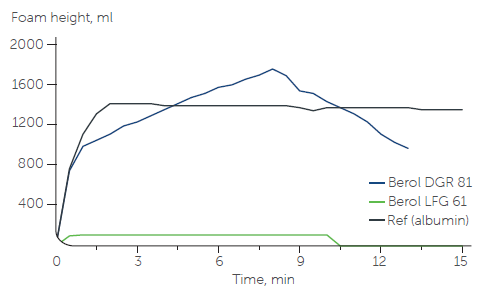

- Foaming Test Data

Foaming: In many applications low foam is required. Berol LFG 61 is low foaming even at high concentrations. In CIP (Cleaning in Place) it is not enough to have a low foaming product, it also has to be de-foaming. In breweries, dairies and machine dishwashing, highly alkaline cleaning products are used, and here it is important not only to clean but also to eliminate protein foam. Berol LFG 61 has de-foaming properties on protein foam. This makes it suitable for use in re-circulating cleaning processes within the food industry. In some applications foaming is important.

Foam height Berol LFG 61

Foaming profile of Berol LFG 61 when tested in the circulation method. Albumin was used as foaming agent. The graph shows that Berol LFG 61 provides anti-foaming properties in this system.

- Cloud Point Test Data

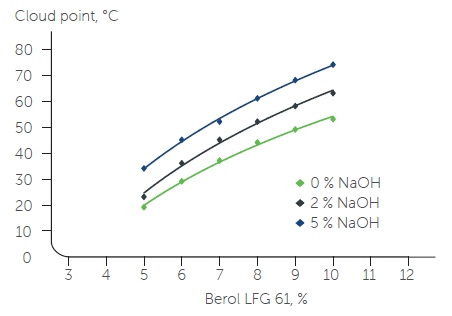

The cloud point increases with increasing amount of product and/or increasing amount of NaOH. It is very similar for the two blends and follows the same trend. Increasing the amount of chelating agent in the formulation has a decreasing effect on the cloud point.

Cloud point Berol LFG 61 + NaOH

Graph: x% Product, 0, 2 and 5% NaOH, 10% Dissolvine GL-47-S and balance with demineralized water