Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Chemical Name

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Working Procedure

Fabrication of PVC products requires the addition of thermal stabilizers. Milling or other processing of unstabilized PVC at elevated temperatures rapidly results in degradation,

the indications of which are: discoloration, formation of hydrogen chloride and irreversible adhesion to equipment surfaces.PVC discoloration is caused by the formation of conjugated double bonds in the PVC polymer chains as a result of the elimination of hydrogen chloride. The HCl formed during this reaction further catalyzes the decomposition of the PVC.

Advera 401P zeolite scavenges the HCI, thereby reducing the concentration. This results in a decrease in discoloration and slower decomposition of the PVC. In stabilization systems based on zinc stearate, the stearic acid groups attach to the PVC polymer chains to stop further formation of the conjugated double bonds.

In that reaction, zinc chloride is formed, which catalyzes PVC decomposition. Removal of the zinc chloride results in greater stability. Advera 401P zeolite is very effective as a zinc chloride or tin chloride scavenger. It reacts with zinc chloride forming chemical bonds with the zinc and forming .sodium chloride within the crystalline structure.

Features & Benefits

Applications & Uses

- Applicable Processes

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Advantages

There is strong public and regulatory pressure to reduce the use of stabilizers based on heavy metals such as lead, cadmium and barium.

PVC stabilizers based on zinc and calcium organic compounds combined with Advera 401P zeolite offer significant benefits, lower toxicity and are environmentally friendly.

Advera 401P zeolite can also be used with other PVC stabilization systems. In rigid PVC applications, the most commonly used stabiliz-ers are alkyl tin mercaptides.

Advera 401P zeolite can reduce costs by replacing as much as 50% by weight of the tin stabilizer while maintaining equivalent dynamic thermal stability.

Properties

- Color (Properties)

- Physical Form

- Odor

- Odorless

- Typical Properties

Value Units Test Method / Conditions Average Particle Size 3 - 5 microns (µm) - - Zinc Stearate/Advera® 401P Zeolite Stabilized Flexible PVC

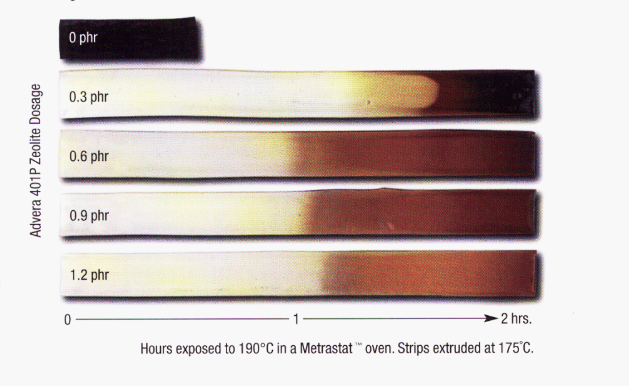

It can be seen that the zeolite costablizer level affects initial yellowness, early color and the total thermal stability of the PVC produced. The formulation with 0.3 phr

of Advera 401P zeolite has the optimum early color hold and lowest yellowness.- Dynamic Thermal Stability of Zinc Stearate/Advera® 401P Zeolite Stabilized Flexible PVC Compounds

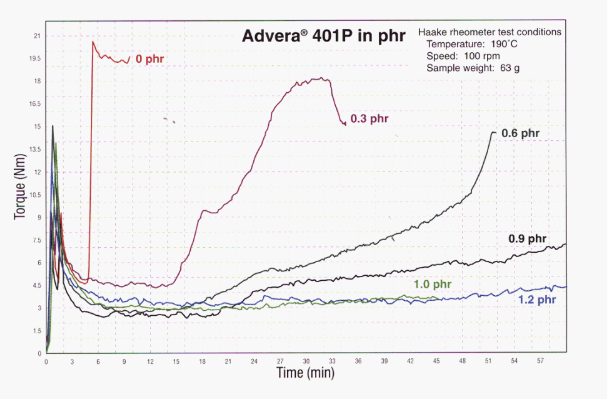

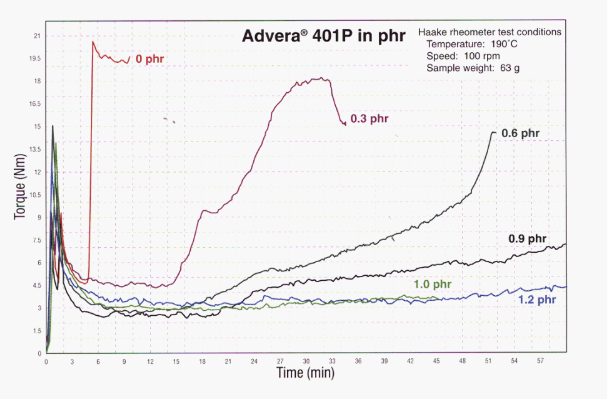

The torque versus time curves for the formulations. The dynamic thermal stability of the formulation increases with increased levels of Advera 401P zeolite, reaching a maximum stability at about 1.0 phr.

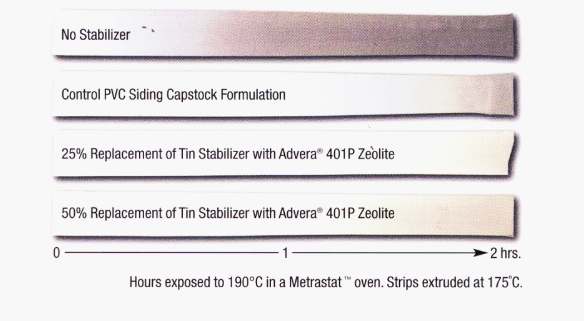

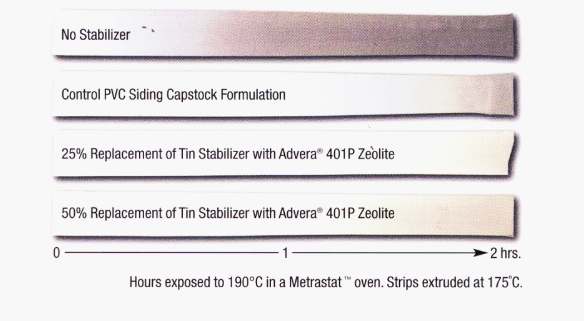

- PVC Capstock Siding Formulations With 25 and 50% of Advera® 401P Zeolite Replacing Methyl Tin Mercaptide Stabilizer

The data illustrate that replacement of 25 to 50% of the methyl tin mercaptide stabilizer with Advera 401P zeolite has no significant effect on the initial color stability of

the PVC formulation.Dynamic thermal stability testing of these formulations showed no loss of thermal stability at up to 50% replacement.

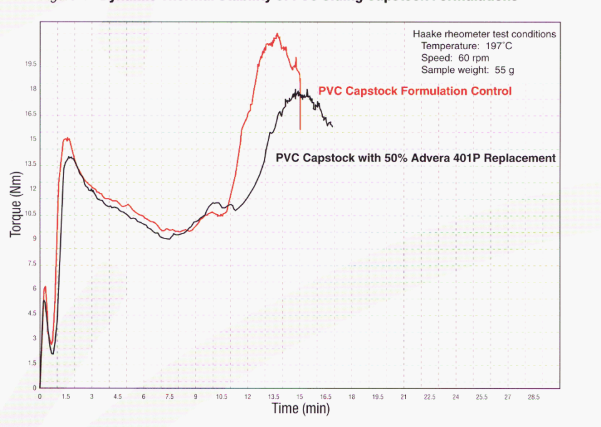

- Dynamic Thermal Stability of PVC Siding Capstock Formulations

Shows the torque vs. time diagrams generated using a Haake torque rheometer for the control PVC and for the formulation in which 50% of the tin stabilizer was replaced with Advera 401P zeolite.

It can be seen from the figure that there is no difference in the thermal stability and rheology between the compounds with and without the Advera 401P zeolite.

Compatibility of Advera® 401P Zeolite With Other Ingredients in PVC Stabilization Systems Advera 401P zeolite can be used with other organic costabilizers for PVC such as

B-diketones.For PVC compounding with Advera 401P zeolite, lubricants with no metal groups are generally preferred. Use of high levels of calcium stearate lubricant in PVC formulations with Advera 401P zeolite may result in a slight increase of yellowness in some PVC compounds.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Formulation

Component Dosage - phr

(parts per hundred PVC resin)Stabilizer System Components

Suggested RangePVC resin (K = 69) 100 DOP Plasticizer

50 Epoxydized Soybean Oil 2 1 to 5 Zinc Stearate 0.3 0.2 to 0.4 Advera® 401P Zeolite 0.3 0.3 to 1.2 Oxydized PE 0.2 The amount of Advera 401P zeolite to be used in flexible PVC formulations is application and formulation dependent.

The optimum amount of Advera 401P zeolite needed for a particular PVC application should be determined experi- mentally in order to take into consideration the final product requirements and the compounding and processing conditions to be used.

A flexible PVC formulation used in PQ Corporation thermal stability testing studies. Advera 401P zeolite was tested at various levels (0, 0.3, 0.6, 0.9, 1.0, 1.2 phr) as a

costabilizer in the test formulation in order to observe the effect of the level on PVC thermal stability.The formulations were extruded at 175°C. One-inch wide strips were used for oven thermal stability testing in a Metrastat™ oven at 190°C for 2 hours.

- Suggested Advera® 401P Zeolite Replacement Levels for Sn Stabilizers in Rigid PVC

PVC Applications Advera® 401P Zeolite

Replacement Dosage - phr

(parts per hundred PVC resin)Percentage of

Tin Stabilizer

Replacement (%)Pipe 0.1 25 Conduit 0.1 25 Siding capstock 0.47 37.5 Siding substrate 0.3 37.5 PVC foamed sheet 0.45 37.5 PVC foamed profiles 0.56 30 Opaque bottles 0.6 2.5 to 15 Transparent calendering 0.05 - 0.3 30 Opaque calendering 0.6 37.5 Pipe fittings 0.6 37.5 to 50* Injection molding 0.75 - 1.50* The suggested Advera 401P zeolite replacement levels for tin mercaptide stabilizers in selected PVC application areas.

The suggested replacement levels were obtained by testing a typical PVC formulation used for the particular application.

The partial replacement of the tin stabilizer with Advera 401P zeolite in the typical formulations maintains or exceeds the early color and DTS time of the control formulation.

Generally, PQ Corporation has found that partial replacement of the liquid tin stabilizer with Advera 401P zeolite may require an upward adjustment of the external lubricant level.

- Typical PVC Siding Capstock Extrusion Formulation

Components Dosage (phr) PVC (K = 69) 100 Paraloid® KM334 5 Paraloid® K120N 1.5 Advastab® TM 181 1.25 Paraffin Wax 165 1.2 Calcium Stearate 1.2 Oxydized PE 0.15 Omya Carb™-1 Calcium Carbonate 2 TiO, 10 To illustrate the results obtained by partially replacing tin stabilizers with Advera 401P zeolite, a typical PVC siding capstock extrusion formulation was compounded.

In the PVC siding capstock extrusion formulation, 25 and 50% of Advastab® TM181 methyl tin mercaptide stabilizer was replaced by Advera 401P zeolite.

The formulations were extruded at 175°C. One-inch wide strips were used for oven thermal stability testing. The strips were tested in a Metrastat'™ oven at 190°C for 2 hours.

Packaging & Availability

- Supplied by